News

Cut Resistance – The Sharp Side of Safety in the Manufacturing Industry

Safety is paramount in any manufacturing environment, especially in the manufacturing industry where workers are exposed to potentially dangerous situations on a daily basis. An essential aspect of this safety is protecting workers from cuts, a common risk when handling sharp materials and tools.

The manufacturing industry includes all companies and processes involved in making stuff. This can be anything from cars and electronics to clothing and furniture. It’s all about transforming raw materials or parts into finished products that people can use.

In these industries, where machine work and handling sharp tools are everyday occurrences, ensuring cut safety should be a top priority.

In this article, we will take a closer look at the standards that are important when selecting cut-safe gloves for use in the manufacturing industry. We will cover various aspects, including European standards such as EN 388:2016+A1:2018, which assess the performance of protective gloves against mechanical hazards. We will also provide examples of gloves that meet different cut classes, ranging from light protection to heavy industrial applications.

In the manufacturing industry, employees face a variety of cut protection risks. Some of these risks include:

- Machines and tools: The use of machines and tools increases the risk of contact with sharp edges of metal parts.

- Materials: Processes in the manufacturing industry, such as handling metal materials or glass, increase the risk of contact with sharp edges.

- Work Environment: Manufacturing work environments can include sharp edges and rough surfaces.

In general, workers in the manufacturing industry are constantly exposed to various cutting hazards, and proper hand protection is critical to prevent cuts and ensure workplace safety.

EN 388:2016+A1:2018 – Protection against mechanical risks.

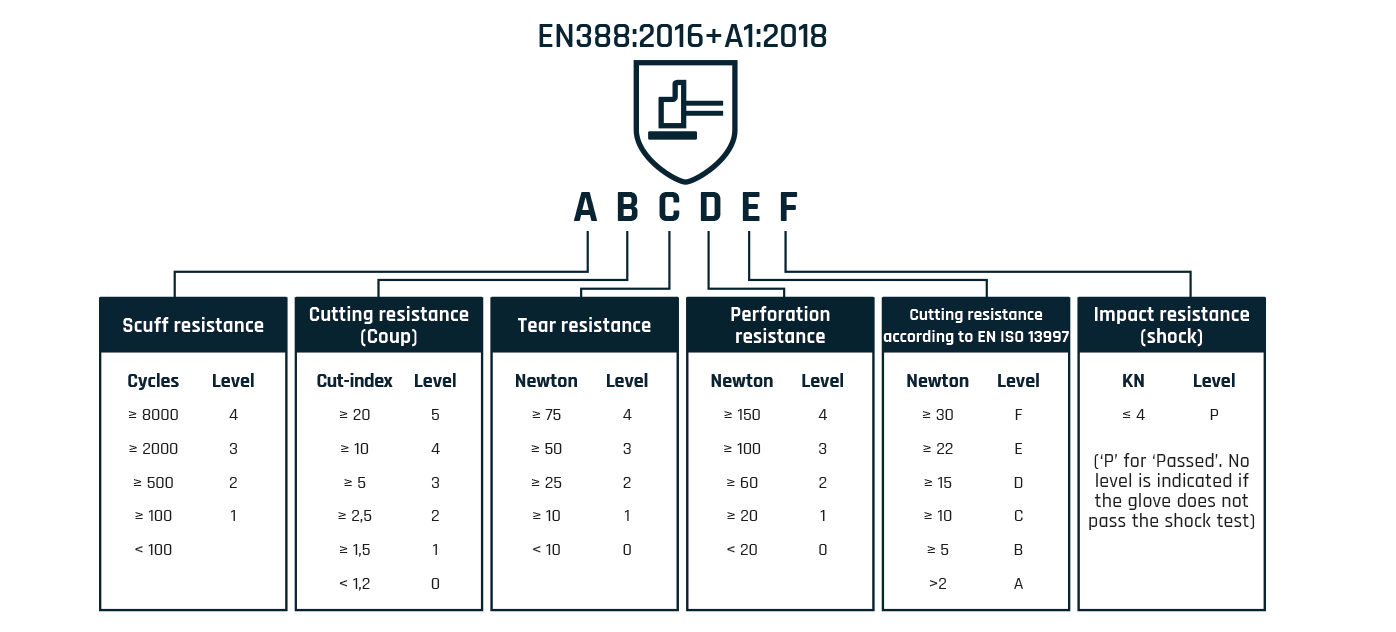

This standard defines performance values for the resistance of gloves to mechanical risks such as abrasion, cut, tear, puncture and, where applicable, impact. Below the pictogram are four numbers and two letters indicating the performance level for a specific risk.

In standards EN 388, the “X” stands for “not tested” or “not applicable” to a specific feature of the glove. This means that the feature in question has not been assessed according to the standards testing methods. For example, if a glove is rated 3X43C, this means that the glove has not been tested for cut resistance, but has been tested for abrasion resistance (3), tear resistance (4), puncture resistance (3) and cut resistance according to EN ISO 13997 (C).

EN ISO 13997: Cut resistance

In many cases, work gloves refer to different cut class levels, with these classes corresponding to performance levels A through F as defined by the EN ISO 13997 standard. It is a convenient way to quickly understand what level of protection a glove provides without having to go into detail about the testing methods and results.

- Cutting class A

Minimum cut risks, for example in finer inspection and assembly work. - Cutting class B

Slight cut risks, for example in light industrial tasks where workers come into contact with sharp-edged materials such as packaging materials. - Cutting class C

Moderate cutting risks, in environments where employees are exposed to high cutting hazards. - Cutting class D

Significant cutting hazards, for example when working with heavier machines and tools, such as industrial cutters or heavy knives. - Cutting class E

High cutting hazards, in very heavy industrial applications such as when cutting high-density glass panels. - Cutting class F

Very high cutting risks, for example specialized industrial applications such as when working in metalworking or performing precision cutting.

Cutting classes in practice

We do not carry cutting class A as cut resistant gloves, as they only protect against minimal risks. We show a glove for cutting classes B through F, to give an idea of the different options available depending on the degree of cutting risk:

| CUTTING CLASS B | CUTTING CLASS C | CUTTING CLASS D | CUTTING CLASS E | CUTTING CLASS F |

|

|

|

|

|

| OXXA® X-Diamond-Pro 51-770 |

uvex C500 foam | OXXA® E-Mission-Prime Cut D 52-720 | Showa S-TEX 581 | Ansell HyFlex 11-542 |

| Art. No.: 1.51.770.00 | Art. No.: 1.91.445.00 | Art. No.: 1.52.720.00 | Art. No.: 1.11.556.00 | Art. No.: 1.90.215.00 |

Need help?

With a good understanding of the risks and available protective equipment, companies in the manufacturing industry can create a safer and healthier work environment for their employees. Want advice or additional information on the right products? Contact us today at T. +31 (0)181 47 50 00. Our enthusiastic team will be happy to tell you more!